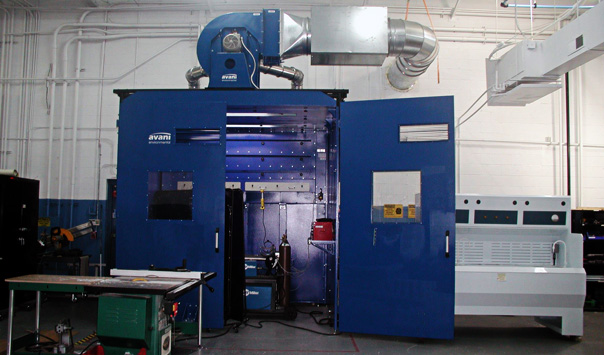

Environmental Booths

Created to meet the demands for environmental booths or more importantly, custom environmental booths for about the same price as competitive cookie cutter booths, Avani Environmental Intl. Inc. is the manufacturer, designer, engineer, installer, and service company. Avani is a one-stop shop.

Avani’s environmental booths provide complete freedom for workers to move effortlessly within the booth to perform any type of the manufacturing process. Most common uses for environmental booths are welding, grinding, sanding, batch mixing, powder coating, painting, or required air quality assembly.

Environmental booths are commonly used where source capture is not practical. Booths can fit anywhere on the plant floor where you have open space. Booths come either self-contained or ducted to a collector away from the booth. Avani offers the standard open booth or forced air return(push-pull) system, which requires less air volumes.

The Avani Features:

- Two configurations (standard or forced air return)

- No hoods or ductwork required on self-contained booths

- Ledgeless construction (reduces dust build-up)

- Non-self contained booths utilizing new or existing dust collectors

- Standard or customized sizes, shapes, and walls

- Easy high-efficiency cartridges (spun bond with Teflon coating or 80/20 cellulose)

- Vertical cartridge removal (no tools required)

- Magnehelic gauge (filter life and required service intervals)

- Easy removable dust drawers (below cartridge service door)

- Single sided service (cartridges & dust drawers)

- Modular design (allows for easy set up and expansion)

- Baffled laminar air floor doors with adjustable inlet slots to balance the system

- Dual sided 12-gauge welded steel walls

- Powder coated (inside/ outside)

- High efficiency premium motors

- Backward Incline Fan (aluminum spark resistance)

- Explosion proof lights and light covers

- Control UL approved control panel (full controls)

- Built-In fork slots for easy placement

- HEPA filter or safety after filter assembly

- Acoustical internal lined steel panels provide the maximum sound absorption

- Vinyl front curtains with adjustable heights to close off booth completely

- Vinyl acoustical fabric (lower cost alternative)

- Vinyl (soft-wall) or PVC side and top panels (cost effective solution)

- Sprinklers or fire surpresant systems

- Digital control panel with touch screen displays

- Variable frequency drives

- Work tables, fixtures, jigs, fume arms, down draft tables, and alternative ducting

- Motor voltages